|

Categories

News & Exhibitions

Applications

Video

|

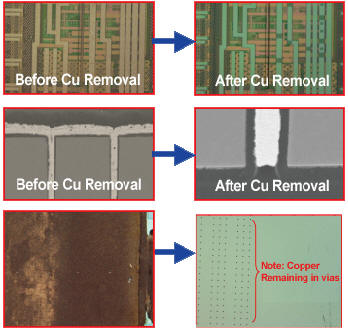

Acid Decap & Delayering Systems

Nisene Awarded Three Patents !Nisene Technology Group has been awarded THREE unique patents on THREE different products/processes for our industry-leading decapsulation equipment.

|

|||||||||||||||||||||||||||||